|

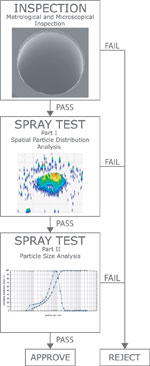

To ensure a consistent spray performance and outstanding quality, each atomizer undergoes several inspection steps during manufacturing and is finally rigorously tested and packaged in our spray lab according to Standard Operating Procedures. Each nozzle is marked with a serial number on body and air cap to ensure proper assembly.

|

|

Atomizer Inspection and Validation

|

Spray characterization is crucial for quality control and optimization of atomizers. For example, a homogeneous and reproducible droplet (particle) size distribution of the spray is one of the most important parameters for an inhalation product. To help our customers ensure that all their atomizers operate within the desired specifications and provide a reproducible performance during the spraying process, ioos systems provides an nozzle inspection and validation service. A wide range of atomizers including various electrostatic, ultrasonic, and pneumatic spray nozzles can be tested. Our testing procedure is based on our long experience in providing production equipment for high demanding applications, such as coating of arterial stents. We can perform the following relevant tests according to the Guidance for Industry for various atomizers, including nasal sprays and inhalers: Particle (droplet) size distribution using Laser Diffraction (Sympatec), spray plume geometry, shape and size, spray distribution using our novel optical Spray Error Patternator. After optical inspection using Digital-Image Microscopy (DIM) spray pattern, spray performance, and droplet size analysis are performed at given process parameters and, if desired, with the customer specific process fluid. To learn more about our unique spray analysis instrumentation and method visit www.spraydiagnostic.com. |

B12 during spray testing |