Design and manufacturing of nano-micro nozzles

ioos is a pioneer in designing and manufacturing micronozzles for biomedical applications. More than thousand of our micronozzles are used wordwide by major medical device and pharmaceutical companies. Our highly skilled personnel micro machines each atomizer with the most sophisticated equipment in house and documents all manufacturing steps. Quality control during production is performed using the latest metrology instruments and microscopy equipment.

What makes a reproducible production of micro-nozzles difficult? Common misconceptions.

“A small nozzle orifice size results in small droplet sizes.” This assumption is often not true, in particular for multiple-fluid or twin-fluid nozzles due to high demanding tolerance and surface finish requirements. Seemingly small manufacturing errors have a big impact on the spray performance of nozzles with a small orifice. Poorly designed and manufactured micro nozzles may therefore perform worse than larger scale nozzles. The presumption for a successful miniaturization and small droplet sizes is consequently the nozzle design and fabrication technique employed. Micro-nozzles should be designed and precision machined to prevent manufacturing errors and improper assembly. For example, the liquid nozzle and the inner contour of the gas cap should be shaped using a special micro-machining procedure to maximize the concentricity and surface finish of the atomizing end. It is important that the concentricity of the gas and liquid orifice is ensured by tight tolerances and the use of centering sections.

It is assumed that “an equal width of the annular gap between liquid and gas orifice results in a homogenous gas velocity distribution.”

However, a poor nozzle performance in terms of droplet size and distribution is often not caused by an unequal width of the annular gap.

The presumption for a good spray performance is the homogeneity of the gas velocity distribution within the tip, which is ensured by its shape and quality.

This translates, for instance in a spray with homogenous spray density distribution.

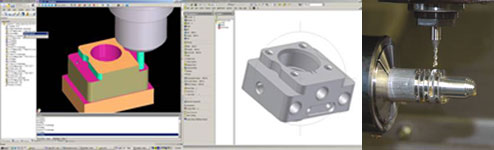

CAD-CAM and Micromanufacturing